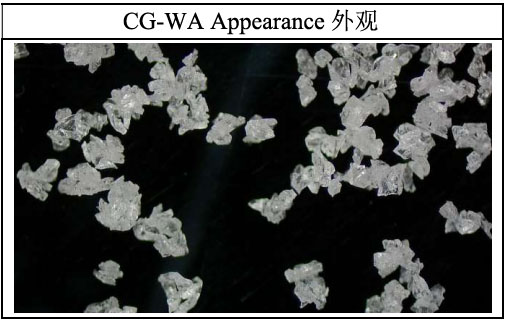

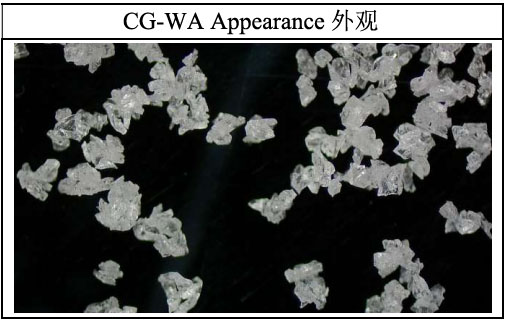

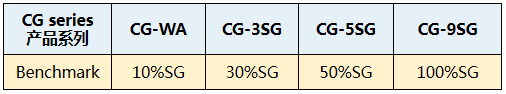

code:CG-WA

CG-WA is use inorganic binder to bind several alumina grains(20um to 100um) together, have sharp blade in every direction and introduce natural porosity to abrasive tools.

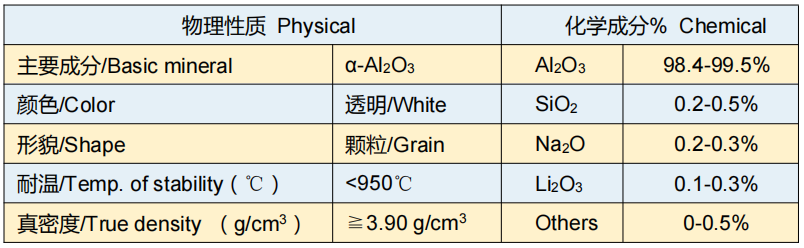

TYPICAL PROPERTTY:

CG – Application for Vitrified Wheel:

1.Benefit of CG for V-bond wheel

l More open structure by bigger porosity

l More uniform of wheel and controlled porosity by precise OD

l Porosity inducer not needed

2. Mainly application

l Creep feeding

l Gear Grinding(Form/Bevel/Worm)

CG – Application concept – Resin bond wheel:

1.Benefit of CG for R-bond wheel

l More sharpness from CG grains continuous tear off

l More stiffness by CG grains support

l More open structure by bigger porosity

l More uniform of wheel by precise OD

2. Mainly application

l Hot/Cold mill roll application

l Fine grinding( grit size 400 or more fine)

l Double flat application

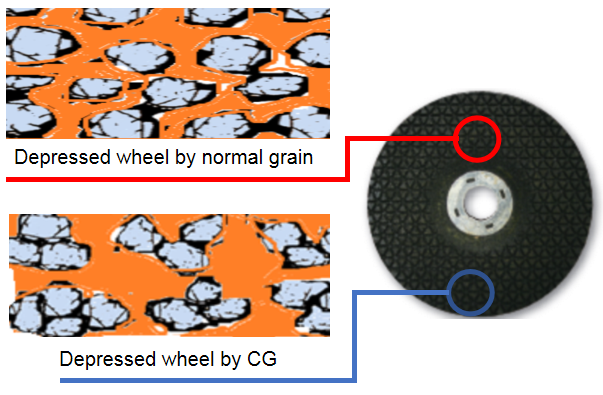

CG Application for Depressed Wheel:

1.Benefit of CG for Depressed Wheel

l More open structure by bigger CG OD and high efficiency

l Stable working condition and performance

l Use fine grains to achieve fine roughness

2. Mainly application

l Auto grinding application

l High surface roughness requirement application

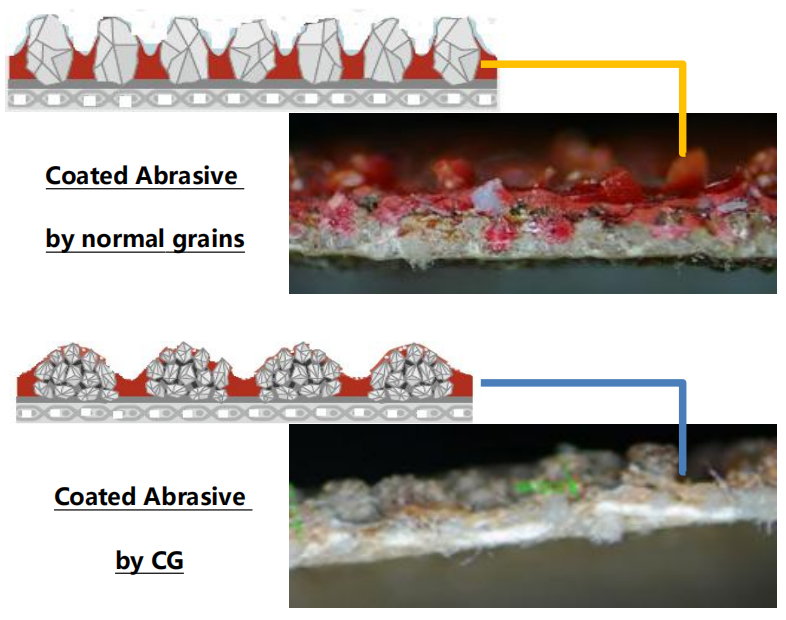

CG – Application concept – Coated Abrasive

1.Benefit of CG for Coated Abrasive

l More sharpness from CG grains continuous tear off

l Stable working condition

l Use fine grains to achieve fine roughness

l Longer life and stable performance

2. Mainly application

l Lower pressure application

l High roughness requirement application